1. Choosing the Right Material

The quality of your custom cabinets starts with the plywood(materials), and this is also where prices can vary massively. Common materials for kitchen cabinets include: multi-ply wood, particle board, fireproof board, stainless steel, and MDF (medium-density fiberboard). Picking the right material is key for both the lifespan and appearance of your cabinets.

Overall, I’d recommend going for MDF or multi-ply wood. They’re relatively affordable and hold up well in terms of other performance factors. Also, make sure to go with well-known brand materials. A brand with high export volumes doesn’t just show company strength – it usually means better quality and after-sales service. Take the brand CONSMOS for example: their materials are exported globally, shipping nearly 15,000 containers every year. With that kind of scale, they’re constantly upgrading their quality to expand into more markets, so you know their quality of furniture is aslo trustworthy.

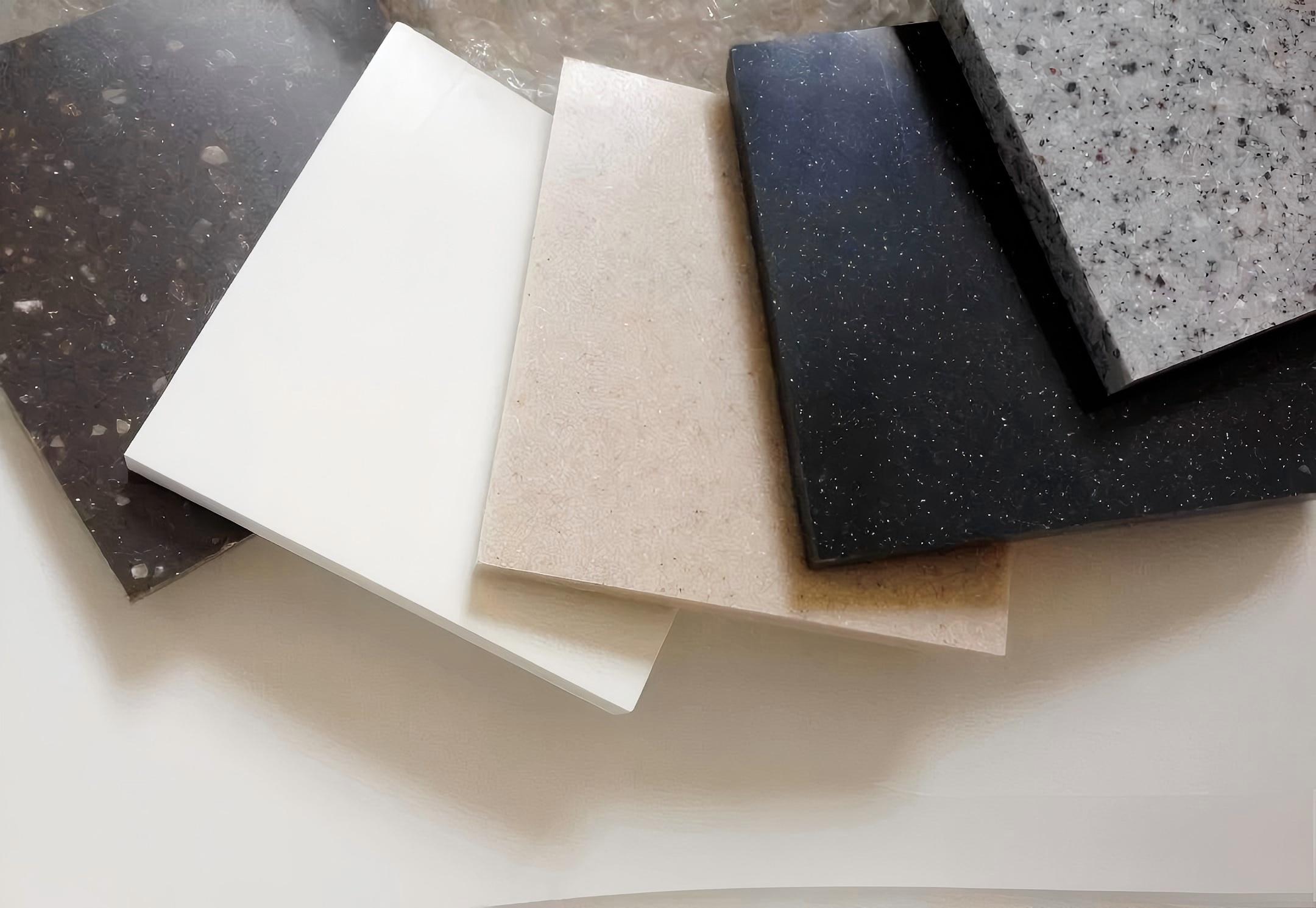

2. Countertop Materials

3. Cabinet Body Thickness

4. Back Board Edge Banding

For the edge banding of the cabinet back panel, double-sided edge banding is essential – do not assume that hidden areas can be omitted. Using single-sided edge banding only will significantly compromise the cabinet’s moisture and mold resistance, as the unprotected edges are prone to absorbing humidity and developing mold over time.